-

OEM Wholesale Christmas Snow Globes LQ24005589

-

Customized Snowball Foxes in Forest with Deer Winter L11202

-

Custom handmade crafts Christmas tree hanging ornaments

-

Resin Christmas tree miniature village glass snow ball

-

Christmas African black Santa Claus figurine desktop decoration

-

Christmas statue decor cute resin Santa Claus seated figurine

-

Halloween home outdoor resin ghosts pumpkin statue ornaments gifts

-

Halloween outdoor decor resin high ghost figurine ornaments

-

Halloween outdoor horror resin pumpkin figurines ornaments

-

Mexican Day of the Dead animal resin cat figurines decoration

-

Day of the dead statue resin french bulldog figurines decor

-

Halloween outdoor horror cute dwarf ghost figurine ornaments

-

Rustom resin easter gifts easter egg basket decoration

-

Resin custom eggs basket decoration home decor easter gifts

-

Resin Easter home decoration custom easter egg basket decor

-

customized Easter Gift Art home decoration

-

Resin Colorful Eggs for Easter gift decorations ornaments

-

Polyresin custom Easter bunny figurines with carrot

-

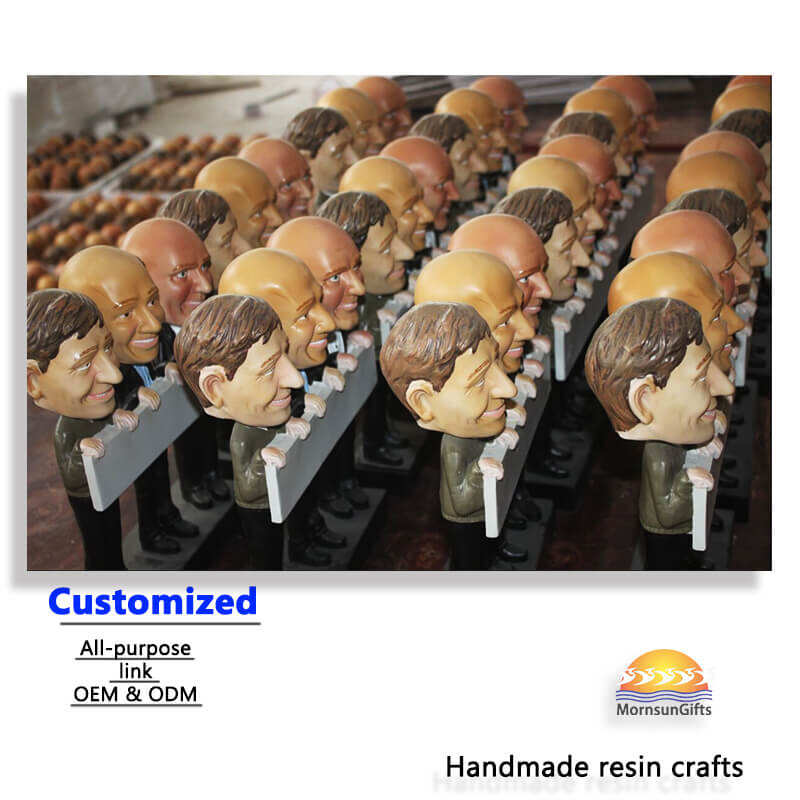

custom resin craft miniature stand action figure figurines

-

Home decoration collection pop mini 3d action character statues

-

Miniature anime art statues custom resin mini figure figurines

-

Exquisite Handmade Resin Fireman Statue Firefighters Figurine

-

Wholesale Handmade Custom Resin Statues Polyresin Catholic Saints and Virgin Mary Resin Figurines for Christmas Nativity

-

OEM Wholesale Unique Resin Crafts Our Lady of Fatima Statue Crown Praying Statue for Decoration

-

Resin black bald eagle art plaque wall hanging sculpture ornament

-

Wall decor resin black lion head sculpture plaque 3D art sculpture

-

Resin black beach coconut tree art wall sculpture decoration plaque

-

Nordic resin desktop vintage ornate wall A4 picture frame home decor

-

Nordic decor ornate wall a4 3d resin emboss black photo frame

-

Nordic home decoration ornate A4 3D resin emboss picture frame

-

Resin ancient architecture custom building of the Colosseum

-

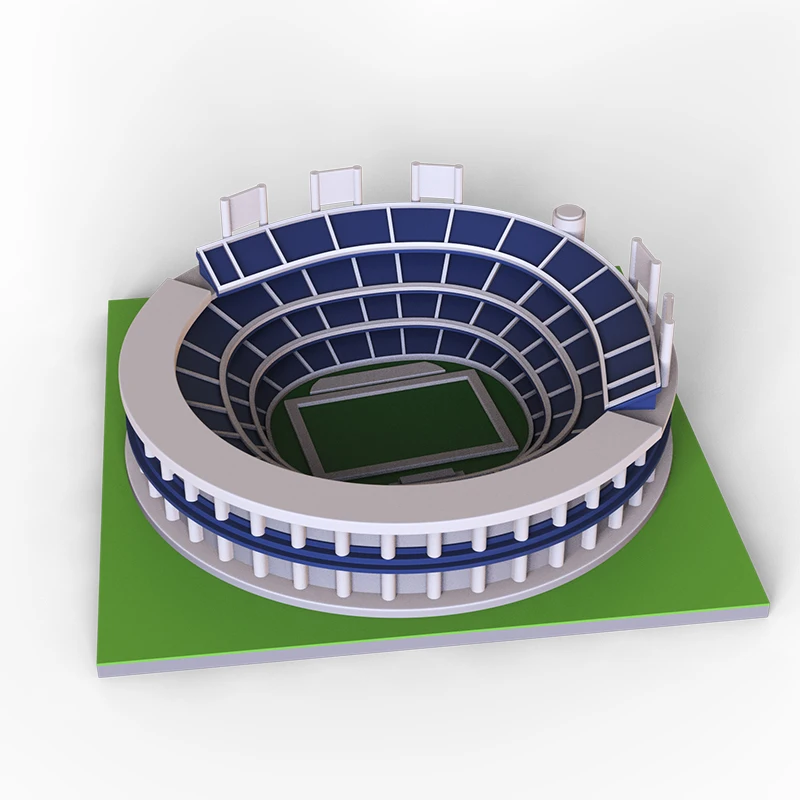

Custom 3D building model figurines polyresin model figurines

-

Custom mini souvenir miniature rugby stadium resin sculpture model

-

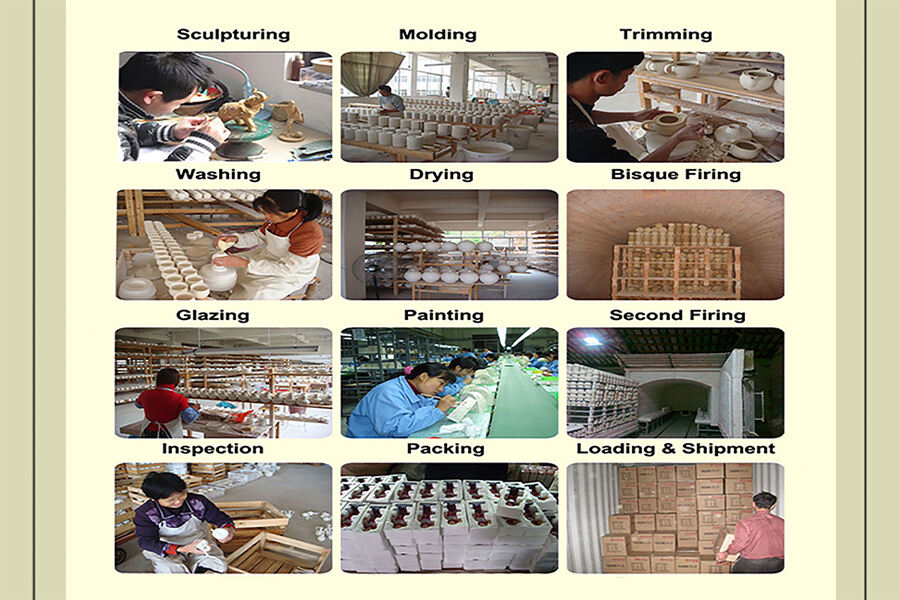

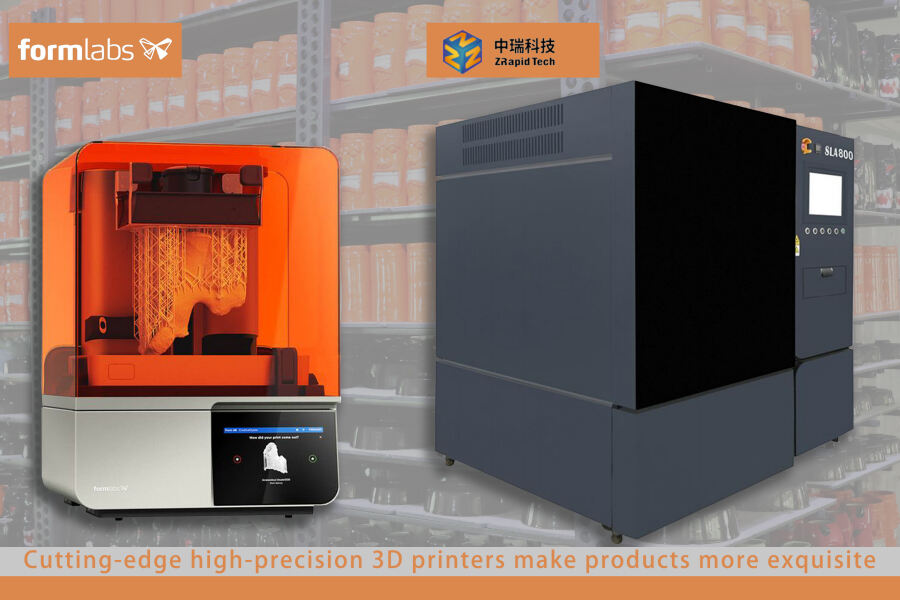

Direct factory manufacturer supplier handmade custom high end good quality professional OEM and ODM resin ceramic crafts

-

Custom handmade religious resin Jesus sculpture figurines

-

Religious decoration resin bronze Jesus sculpture figurines